If you're working on a project that needs a drainage system, you already know the importance of a good design to remove water safely and efficiently. Whether you are handling stormwater or wastewater, effective removal of water prevents damage to important assets, creates a safe, hazard-free environment for occupants, and eliminates water stagnation and associated health and safety issues.

A well-designed linear drainage system addresses all these issues while still considering installation time, cost and ongoing performance as well as flow velocity, resilience, installation time and lifetime maintenance cost.

With so many variables at play, it's important to have a clear understanding of the different types of drainage systems available today.

Here is a guide to break down the various options and help you make the right decision for your needs.

Swale Drains

Appearance

Swale drains are, in essence, a shallow ditch lined with turf grass or similar vegetation. They are a broader and more shallow system, which makes them more subtle than traditional trench-style systems.

What They Do

Swale drains are used to help slow and control water runoff that occurs outdoors. They also help to prevent any water from flooding, puddling or eroding the surrounding soil. They also help keep storm drains from being overwhelmed by a sudden influx of water by spreading water on a larger surface and keep the runoff from draining too quickly.

Where You Find Them

This system is commonly found around both residential and commercial areas of landscaping.

Point Drains

Appearance

This is a subsurface system that requires floors to be sloped in the direction of the drain. When multiple drains are needed, this can create an unattractive, unleveled appearance and result in difficulties in planning and setting up the facility.

What They Do

These drains work by collecting water from a single point or gully, like the drain you find in the middle of a shower.

Where You Find Them

Point drains are common in places where drainage is needed from a specific point due to structural or topographical needs.

French Drain

Appearance

It is a subsurface structure that consists of a perforated pipe that is installed flat in a yard with a sloped trench that helps move water runoff from a highest point at the start to the lowest at the end, where it goes into a sewer, cistern, or swale.

What They Do

French drains help to redirect water from wherever the drain starts–usually close to the foundation of a structure–to some sort of sewer or cistern. In general, French drains are used to help the natural flow of water from high to low.

Where You Find Them

French drains are a common system used in residential areas to redirect water away from homes and landscaping.

Trench Drains

There are many different types of drainage systems that fall under the “trench drain” umbrella, from the standard trench drain to more specific kinds.

Appearance

Unlike other systems on the list, trench drains are a surface system. In essence, a trench drain consists of a large trench that has a drain channel set in place with concrete. This channel can be very narrow or very wide and is usually covered with a heavy metal grate.

What They Do

Trench drains work by intercepting the flow of water runoff over vast expanses of ground. They take the water from the surface of the ground and through the channel, where it eventually reaches a final drainage point.

Where You Find Them

These systems are usually found around commercial buildings, including restaurants and loading docks. You can also find them on city streets and even pool decks.

HDPE Drains

High-density polyethylene trench drains are a newer innovation in terms of drainage systems that have become popular.

Appearance

These systems have pre-engineered, modular channel sections that are lightweight and easy to install. They are smooth in texture and highly durable as well. Like with tradition trench drains, HDPE systems still require a grate covering.

What They Do

Like your regular trench drain system, HDPE drains work by redirecting water from the surface of an area to the drain channel where it can be moved to a disposal area, such as sewage.

Where You Find Them

Because of their high chemical resistance and overall durability, HDPE drains are an excellent option for industrial applications.

Cast-In-Place Trench Drains

Appearance

Of all the different types of drainage systems, this one can be most problematic. To install, a trench is dug, then wood forms are put in place with a reinforcing bar before the casting the trench with concrete. Like other trench systems discussed thus far, this one also requires a grate covering.

What They Do

These systems redirect water, and even debris, from the floor surface into the channel and through a catch system, helping to keep floors clean and dry, unless the channel gets clogged.

Where You Find Them

These were common in various industries, but due to their cost and inefficiency, many have turned to better alternatives.

Slot Drain

Finally, in looking at the different types of drainage systems, there is the newer and more innovative type of trench drain called the Slot Drain.

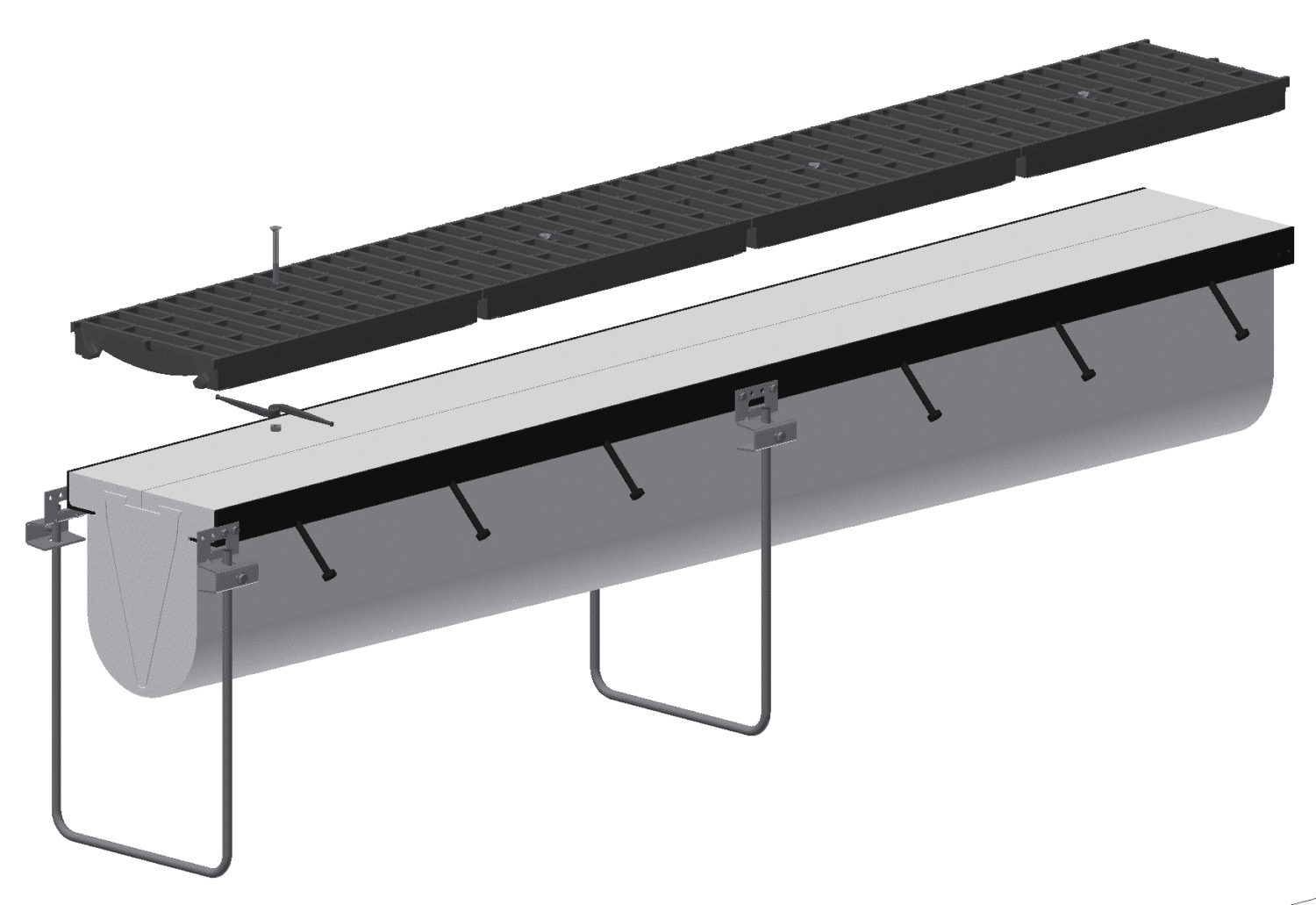

Appearance

The Slot Drain’s appearance is unique when compared to other systems because it comes as a pre-sloped and pre-assembled single piece of surface drainage. Unlike other types of trench drains, the Slot Drain has a slimmer design which eliminates the need for a grate covering. It comes with different material options, including a popular and durable food-grade stainless steel.

What It Does

With sloped floors, water will flow to the drain channel, where it can work it’s way to a collection tank for disposal. This allows floors to dry quickly and prevents people from slipping and falling on wet surfaces.

Where You Find Them

Slot Drain is the most versatile system on the market, with different options that work for virtually every industry, and even residential areas and homes.

There are so many different types of drainage systems, it can be overwhelming. But, taking the time to read a little about what each one does and what they are suitable for can help a tremendous amount. Not all options work in every area, so you want to be sure to choose the best system for your needs. Slot Drain, however, is a great, versatile option that can work virtually everywhere with little to no issue in installing and maintaining it.

If your project requires point or trench drainage systems, contact us to learn more about Slot Drains. Our experts can help design a system that meets all your needs, and you can enjoy all of the advantages that Slot Drains have to offer with none of the drawbacks of other drainage systems.

Interested to learn how Trench Drains are typically installed? Watch the below video: