Beer is one of the most popular beverages in the world, with numerous options for consumers.

The breweries that make beer come in all sizes, with craft beer more popular than ever. While the size of these breweries may differ, they all have the same general requirements, including reliable floor drainage.

Here is what you should know about brewery drainage requirements.

The Rise of the Brewery

The first recorded brewing of a beer-like beverage dates back to around 7000 BCE, a drink called kui from the ancient Chinese. While kui was the first beer-like beverage, Western cultures credit the Mesopotamians with brewing what they consider to be the first "true" beer, though the date brewing began is unclear. From there, beer spread to other civilizations, including Egypt, Greece, and Rome, before finally reaching the Germans, who began brewing around 800 BCE and turned it into the drink we know today.

Commercial brewing arrived in North America in 1632 and slowly rose to popularity. The more the nation expanded, the more breweries opened up in new places. While there are many large brewers, consumers are turning to independent brewers who focus more on quality than quantity.

According to a 2022 Brewer's Association report, small breweries reached an all-time high, with 9,552 open nationwide. The Association also released the top 50 overall brewing companies of 2022; of the 50 companies, 40 were small and independent brewers.

Why Brewery Drainage Matters

Water usage in breweries is very high, often double or triple the beer the brewery produces, and it can be even more in larger-scale breweries.

Regardless of the size of the brewery, the large amount of water usage results in equally large amounts of wastewater, which makes the need for floor drainage critical.

Proper drainage will help to manage and remove wastewater from the ground. It will also:

Allow Floors to Dry

When wastewater has nowhere to go, floors stay wet, which creates slippery, hazardous work conditions for employees. Floor drainage allows them to dry quickly and keep conditions safe.

Remove Harmful Contaminants

Brewery wastewater contains many contaminants, including biochemical oxygen demand (BOD), suspended solids, ammonia, phosphorus, and more. Those are just the contaminants from brewing; there are also contaminants from the cleaning and sanitizing chemicals and domestic wastewater. Managing the wastewater quickly and efficiently is vital to avoiding contamination as well as the growth of harmful pathogens.

Help with Spills

Accidents happen, and sometimes breweries have to deal with major spills, whether during the brewing process or broken bottles from finished beers. No matter where it happens, a drainage system can help clean up the mess.

Brewery Drainage Requirements

Breweries require drainage in many different areas of the brewery. These areas include between fermenters, inside walk-in coolers, bottling and packaging areas, and storage facilities. Drainage for any part of a brewery has specific requirements, including:

Durability

Choosing a suitable material for a brewery drainage system is vital. Whatever material you choose needs to withstand high temperatures and high pH levels. Materials like stainless steel provide the most durability and can withstand the demanding environment of breweries.

Flow Rates

With the large amounts of wastewater in mind, a brewery drainage system must have sufficient flow rate capabilities. Choosing a system somewhat larger than your needs can help to ensure that the system doesn't become overwhelmed and overflow.

Load Bearing

Brewery equipment is heavy, and the wrong drainage system will not last under such weight. The right drainage system must have a heavy-duty load class; a heavy-duty load class means it is durable enough to withstand the weight of pallet jacks and forklifts moving substantial amounts of weight at a time.

Sanitation

Sanitation is one of the most vital brewery drainage requirements. You want a drainage system made with sanitary materials, like stainless steel, which is non-porous and bacteria-resistant. The system's design should also minimize or eliminate grooves, crevices, and seams, so there are as few bacteria-harboring points as possible.

Maintenance

Sanitation is one of the most vital brewery drainage requirements. You want a drainage system made with sanitary materials, like stainless steel, which is non-porous and bacteria-resistant. The system's design should also minimize or eliminate grooves, crevices, and seams, so there are as few bacteria-harboring points as possible.

A Drainage System That Has It All

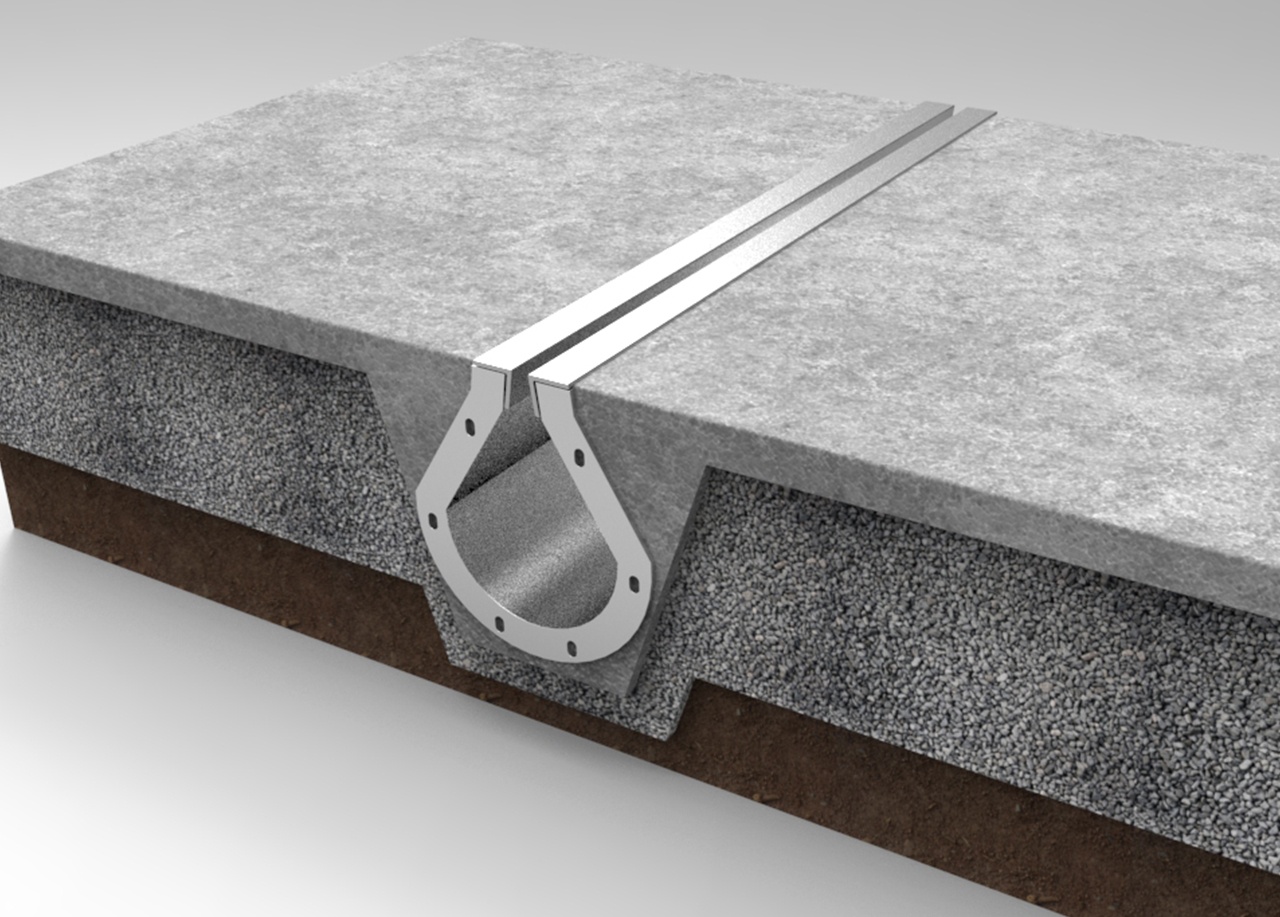

Slot Drain Systems can meet all these needs and more with their unique systems. Their 10,000 and 9,000 Series systems have NSF-certified, seamless designs using T304 and T316 stainless steel. They come pre-assembled, which eliminates connecting grooves and seams, to ensure no bacteria harboring points are present, further ensuring that they are sanitary systems.

Slot Drain Systems can meet all these needs and more with their unique systems. Their 10,000 and 9,000 Series systems have NSF-certified, seamless designs using T304 and T316 stainless steel. They come pre-assembled, which eliminates connecting grooves and seams, to ensure no bacteria harboring points are present, further ensuring that they are sanitary systems.

Unlike a traditional trench drain, the Slot Drain system has an open, grate-free channel that makes inspections and manual cleaning easy. Slot Drain is also compatible with CIP, to make maintenance even more effortless. The open design also creates a more attractive system, so it is an excellent option for tasting rooms that are open to consumers.

Despite the smaller opening, the Slot Drain still offers substantial flow rates. Their largest system, which has a 1.25-inch channel opening, has flow rates of 27 GPM per foot of drain. Both the 10,000 and 9,000 Series also have a Load Class E, a heavy-duty forklift rating, so it is safe for use in breweries. It will not break, bend, or bow under the weight of the equipment, vehicles, or anything else.

Another notable feature is the option to add a Catch Basin and Strainer Basket, which can help catch small objects and debris that end up in the system, to prevent them from getting lost. It has the same sanitary stainless steel design and load-bearing capabilities as the drains.

Proper Drainage - A Brewery’s Best Companion

Beer's popularity isn't going anywhere, and neither are the breweries that make it. A well-equipped brewery ensures that brewers can create quality beers safely and meet the necessary sanitation standards. A floor drain system is one of the most essential elements of a brewery. Slot Drain meets all the brewery drainage requirements while also having a sleek and attractive design.

Contact Slot Drain Systems today to learn more about using Slot Drain in your brewery!