.jpg?width=957&name=slotdrain-2%20(1).jpg)

Just like any food and beverage facility, a brewery requires a great deal of upkeep. Everything has to be adequately cleaned and sanitized on a regular basis to avoid the growth and spread of harmful bacterias which can contaminate the beer.

While the need to clean the equipment and various surfaces is easy to remember, there is one area that tends to be forgotten: the drainage system. This is an area within breweries that can harbor bacterias and odors, which can quickly spread and grow into a severe issue, creating dangerous health problems within the facility.

Clean-in-place, or CIP, is a different method of cleaning the inside of equipment that is much more effective. By using a CIP system brewery, a cleaner, a more sanitary facility can be easily achieved.

What is a CIP System Brewery

Simply put, a brewery CIP system is a cleaning system that is used to clean the interior surfaces of pipes, vessels, and tanks. What makes a CIP system so unique is that the cleaning process can be done not only without disassembling equipment but also without actual manual labor.

While the CIP system is found throughout various industries, brewing CIP systems are especially useful. With the way CIP systems work, it can help breweries save not only a great deal of time but money as well.

Why Brewing CIP System is Important

Before the 1950s, when CIP systems became more commonplace, breweries had to completely disassemble their equipment to clean it. This took a great deal of time, and the frequent disassembly of this equipment could eventually begin to negatively impact the quality of the product.

These days, however, the equipment found in breweries is all closed. A CIP brewing system makes it possible for breweries to clean the internal walls of the brewing equipment without having to disassemble anything. This makes it possible to preserve the internal environment of the equipment, as well as the overall quality of the beer being brewed.

How CIP Systems Work

For CIP brewing to be possible, a brewery’s equipment needs to be made with a CIP system already in place. This system makes it possible for cleaning liquid to automatically be dispersed within the pipes, tank, or other pieces of equipment.

When it is time for cleaning, the brewery CIP system will use liquid pressure to disperse the solution on every part of the equipment’s internal surface. Once the solution has been dispersed, it is repeatedly circulated through the equipment, allowing it to clean dirt and debris as it goes.

Small pieces of equipment, like piping, pumps, valves, and filling machines, which are too small for an internal CIP system are cleaned through an external CIP system brewery. These external systems work by circulating the cleaning solution through the parts where beer comes into contact with.

CIP Systems and Slot Drain

As mentioned before, CIP systems are not just made for the equipment within a brewery. It is also useful for maintaining clean and sanitary floor drainage. The one issue, however, is that grated trench drains can make CIP brewing slightly difficult.

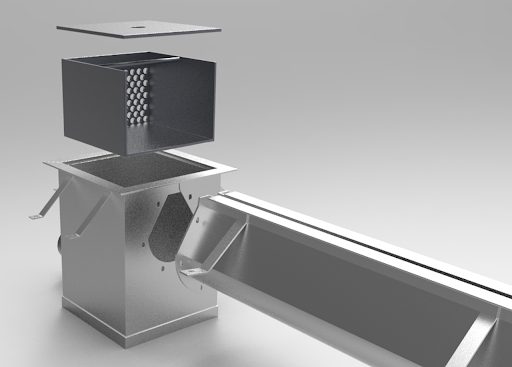

That is where the Slot Drain System comes into play. Because the Slot Drain does not have any grates, it allows a brewing CIP system to work more efficiently.

Slot Drain’s pre-sloped, food-grade stainless steel design already makes it a sanitary, corrosion, bacteria, and heat resistant. But, when their Flush-Flo CIP system is added, it helps to create an even more sanitary brewery.

How Flush-Flo Works

Slot Drain’s Flush-Flo system works just like any other brewery CIP system. The Flush-Flo system gets attached to either a pressurized pump or non-pressurized water line.

When turned on, it creates a strong flow of water and the cleaning solution that travels through the length of the drain surface. This helps to loosen and remove any bacteria and debris and move it towards the catch basin.

To ensure the drain is entirely free of bacteria and debris, a cleaning paddle and brush can also be swept through the entire length. This will remove any remaining unwanted waste to the catch basin, which can then be emptied.

A CIP system is not always cheap, and many small breweries consider foregoing it in favor of manual cleaning. But, when the amount of time that is saved with a CIP system is taken into consideration, it is well worth it. Not only that, but a CIP system brewery will also help ensure that the quality of the beer being produced is not compromised with the constant disassembly of equipment.

While breweries do not have to install CIP systems everywhere all at once, at least having a drainage system like Slot Drain, with a Flush-Flo system included, would be an excellent start and can significantly improve the breweries sanitation level.

Food Safe Drains contains several articles for food and beverage facilities researching the best types of drain systems for their applications.