Food processing manufacturing plants are found all over the world, and new ones are continuously being built. While it may not seem like it by the rate new plants are built, there are certain things that each food processing manufacturing plant must have to operate.

In fact, in the United States, certain government agencies such as the FDA and USDA have strict guidelines for when it comes to building a food processing manufacturing plant. Here are some things to keep in mind when designing and building a new plant.

1. Location

The first thing to keep in mind is the location of the new plant being built. Ideally, it should not be too far from wherever the raw food materials will be coming from. By being within a shorter distance from a farm or other sources, you will be able to cut back on material transport costs to and from the facility.

The location of the plant should also be easily reachable by emergency services such as police and fire and rescue. This is especially important as should an incident occur, emergency crews will not have to travel as far to reach the facility and take care of the issue.

2. Sanitation Area

When workers enter a food facility, they come with outside germs and dirt on their feet and hands. These contaminants have the potential to lead to seriously harmful bacteria, such as Listeria and E.coli, which can destroy food products and leave the entire plant unsanitary and unsafe to function.

A sanitation station should have sink washing stations, lockers, and an area where they can put on sanitary uniforms that cover their hands, feet, hair, and anything else that can be a sanitation issue.

3. Proper Flooring

In many cases, the flooring of a food plant is overlooked or deemed of lesser importance. But choosing the right flooring is a critical part of any food plant.

Flooring should be a smooth coating that has no cracks or crevices where bacteria can get stuck and begin growing and spreading. It should also be easy to clean and maintain and offer some sort of corrosion resistance so that the strong cleaning chemicals used in the plant will not deteriorate too quickly.

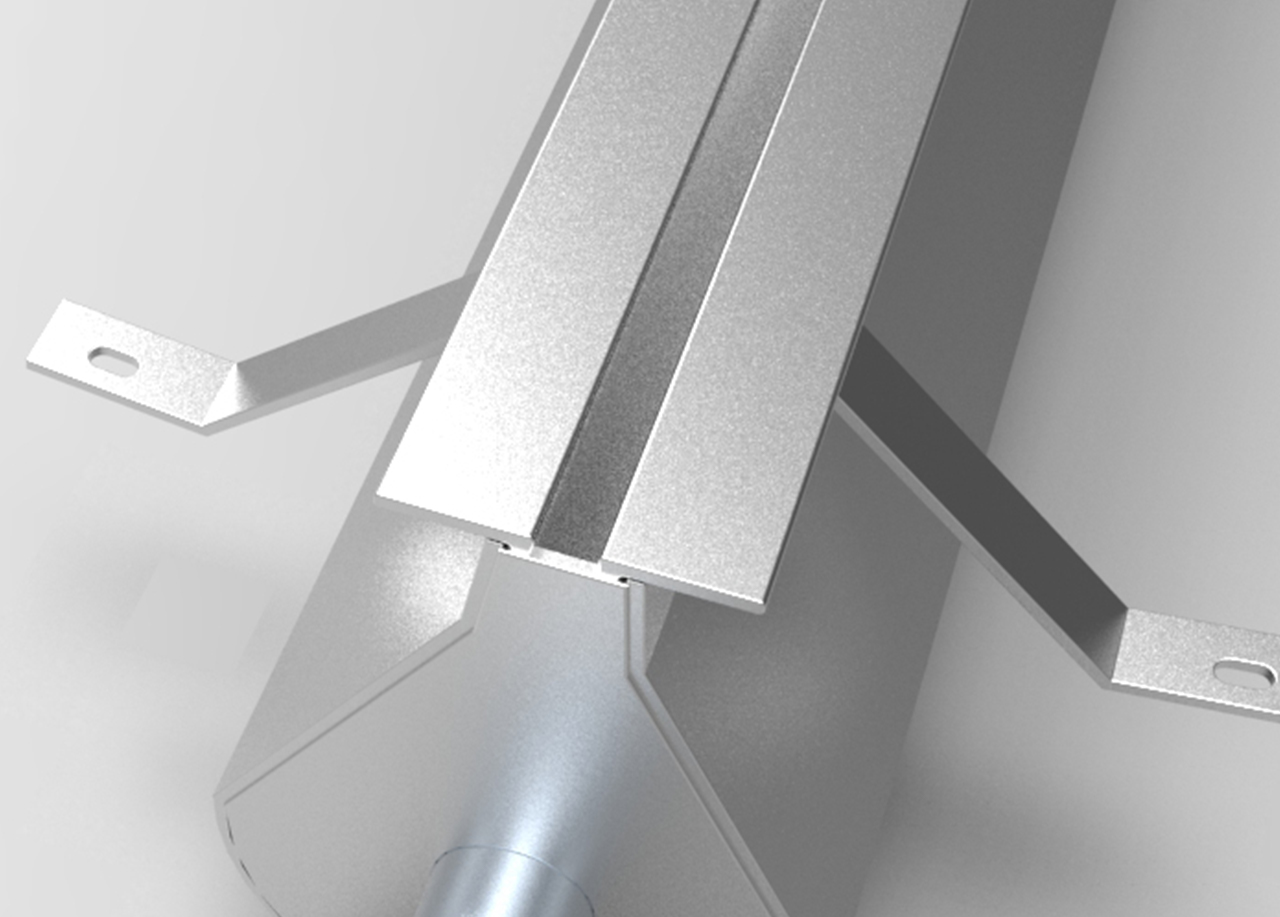

4. A Floor Drainage System

Another area that tends to be overlooked is the need for a good floor drainage system. A floor drainage system can help keep floors clean and free from water or other fluids that can fall onto the ground in a food plant.

Slot Drain is a company that offers unique grate-free floor drains that are highly durable and effective. Their food-grade stainless steel option meets the standards of both the USDA and FDA and are corrosion, bacteria, and odor resistant. Additionally, Slot Drain is ADA Compliant and incredibly easy to clean–there is even the option for a self-cleaning or Clean-In-Place system that will make caring for the drain much easier.

5. High-Quality Equipment

If you are building a food processing manufacturing plant, you should invest in the best equipment you possibly can. This will ensure that your food plant will have no issues working.

Equipment should be stainless steel so that it is bacteria resistant and should also be easy to clean and maintain. If possible, you may even want to check about equipment that is Clean-In-Place compatible, so that a portion of the required daily cleaning can be done automatically.

6. Cleaning Stations

Besides having a sanitation area at the entrance of your facility, you should also have cleaning stations throughout the facility. This will give workers easy access to water hoses, mops, and brooms in case of any spills or other accidents. By having cleaning stations available and easily accessible, your plant will stay cleaner and more sanitary during the workday and workers will have an easier time cleaning up at the end of the day.

7. A Sensible Layout

Finally, another critical factor when it comes to building a food processing manufacturing plant is to have a sensible layout. All of your equipment and areas within the facility should flow in a way that makes sense for the order of the actual food processing that you are doing. That way, employees are not forced to go back and forth between various sections, which can take time away from work and potentially lead to falling or missing steps in food processing.

Building a food processing manufacturing plant isn’t difficult, but you want to be sure you do it right. Keeping these 7 must haves in mind will help to ensure that your plant is set up right from the very beginning. It will also mean that you will be sure to meet the requirements set forth by agencies like the USDA and FDA. Which will mean your plant will be correctly set up, clean, and sanitary.

Food Safe Drains contains several articles for food and beverage facilities researching the best types of drain systems for their applications.