There is a lot that goes on in food processing plants, and sometimes the process is long and drawn out. However, the marketplace is an incredibly competitive place, with new food brands popping up every day, hoping to take on those that already exist. But, for any food brand to find success, they need food manufacturing efficiency.

Tips for Improving Efficiency in your Food Processing Plant

The more efficient a food processing plant is, the more likely it will be to find success and be able to thrive on the market. Here are five ways that a food processing plant can increase efficiency and be more successful:

1. Convert to Energy Efficiency

Food processing plants take a lot of energy to power, from the lights to the machines and equipment. One way to increase food processing efficiency is to make the conversion to a more energy-efficient setup.

Part of creating an energy-efficient food processing plant includes changing equipment and lighting for more efficient options. Choosing Energy Star-rated appliances and equipment will help cut costs and create an overall more efficient operation.

By converting to an energy efficient processing plant, facilities can also significantly reduce their greenhouse gas emissions, lessening their negative impact on the environment.

2. Have a Routine Maintenance Plan

Facilities have many different working parts, and if one of these parts becomes broken or damaged, the facility will not work as efficiently as it should. Because of that, having a routine maintenance plan in place is essential for food processing efficiency.

A maintenance plan should provide guidelines for how to check equipment and how often it should get inspected. An efficient maintenance plan should also detail how employees should clean and sanitize the facility, from the equipment to the floors.

Having a maintenance plan in place will ensure the facility is always functioning at its optimal level, which means it will be more efficient. Beyond that, it will ensure employees will catch any equipment issues before they become more serious problems, which will help to save money in the long run.

3. Have the Right Facility Layout

There is no better way to increase food manufacturing efficiency than to have the right layout. Food manufacturing facilities all follow strict steps of production, so it makes sense for the facility's layout to follow that same line of events.

By following the order of production for the facility layout, it will cut down on production time and allow workers to move more efficiently. It will also help to ensure that workers do not skip steps or contaminate products at varying stages of completion.

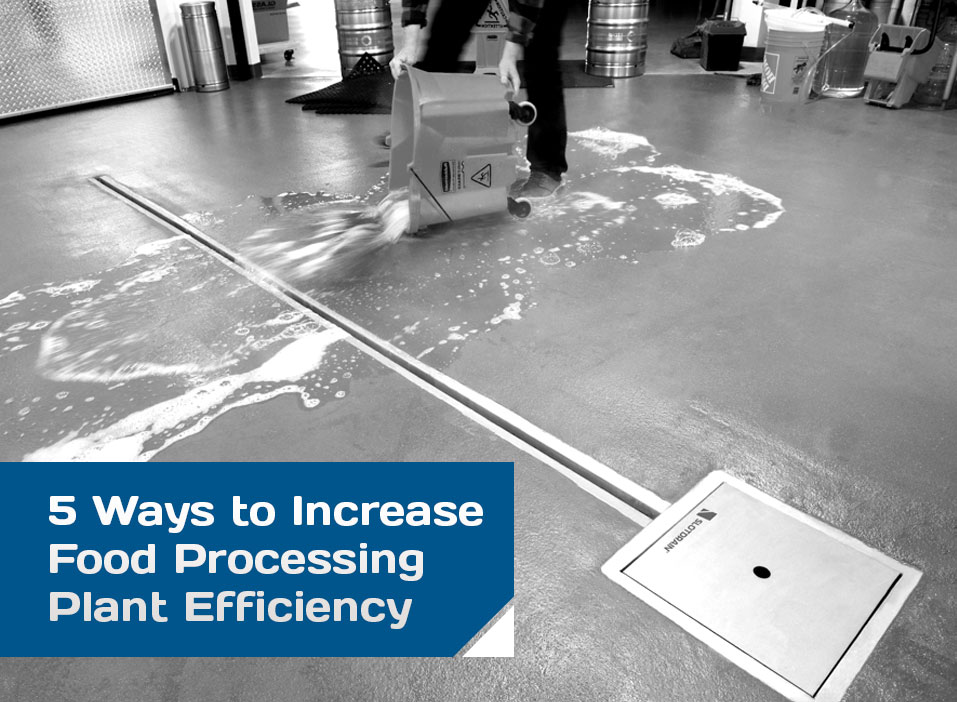

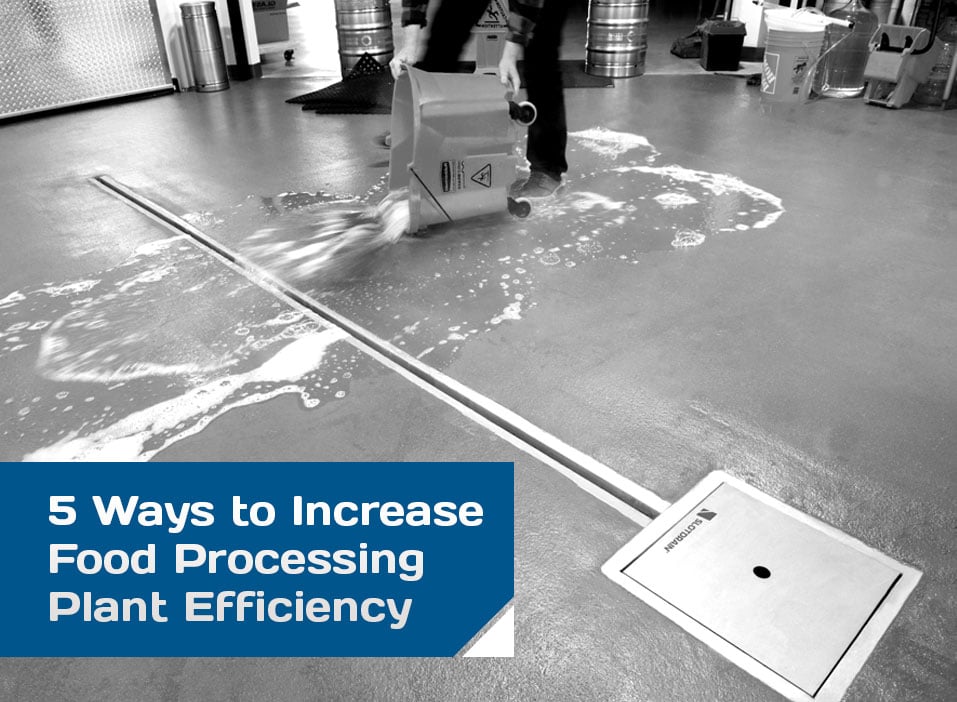

4. Install Slot Drain

Another way to help create more food manufacturing efficiency is by installing a drainage system like the Slot Drain system. This is a style of trench drain that is made of food-grade stainless steel, making it corrosion resistant, bacteria resistant, and resistant to extreme temperatures.

This system comes both pre-sloped and pre-assembled, which helps to make new installations and retrofits easy for a facility. Beyond that, Slot Drain is unique because it does not require a grate covering. Grates are fragile and break easily, which can create serious safety hazards for employees. They are also incredibly heavy, which can result in injuries from trying to lift the cover for drain cleaning.

Another benefit of Slot Drain includes a Load Class F rating, making it capable of withstanding the weight of facility equipment. It is also easy to maintain, ADA compliant, and keeps odors and bacteria from spreading.

5. Improve on Quality Control

One of the biggest issues that food processing plants seem to have is quality control. Products go through production and then get sent to stores for sale quickly. As a result, they can end up being recalled due to some sort of contamination issue — everything from salmonella and e.Coli to small pieces of metal or plastic have been recent reasons for recalls. Regardless of the reason, it is a problem easily avoided with careful attention to quality control.

Take the time to scrutinize food as it moves through the production process. Training employees on what to spot, and investing in equipment to assist with quality control are important to keeping the product safe and sanitary, as well as the safety and health of the employees. Metal detectors and x-ray systems can help decrease the chances of foreign object contamination, while careful handling and storing of ingredients can minimize other types of contamination.

The five methods mentioned above are just a few of the more effective ways to create a more efficient facility. Installing a Slot Drain System will make a significant difference with safety, sanitation and efficiency.