The paper and pulp industry is the industry responsible for taking wood and producing various products such as pulp, paper, paperboard, and other cellulose-based products. First, wood is processed through a pulp mill, where it is turned into a pulpy mixture used to make a wide range of different products. Then the pulp moves to a paper mill, where it becomes the various paper products that are on the market today.

Like with any sort of processing facility, it is essential to have the proper paper and pulp mill drainage in place at both of these facilities. While there are different systems on the market, these mills require efficient systems that can handle the anticipated flow levels, while helping to maintain a clean and sanitary facility. Slot Drain can meet all of the necessary needs of these mills to ensure they have well-functioning, efficient drainage systems.

Traditional Paper and Pulp Mill Drainage Problems

Here are four of the most common problems faced by traditional paper and pulp mill drainage systems, and how Slot Drain's unique and modern drainage solutions can help solve them:

1. The Mill's Machinery is too Heavy

Even in paper and pulp mills, you are likely to find lots of large, heavy machinery and equipment. This equipment is sometimes placed on top of the facility's drainage system, which puts a great deal of weight on the drain. It can even cause the drain to break and give out under the added strain which can force the mill to have to pay for a costly replacement. Not only is that be an added expense, but it can also slow down work, which would mean the mill will not make any money until the repairs or replacement is in place.

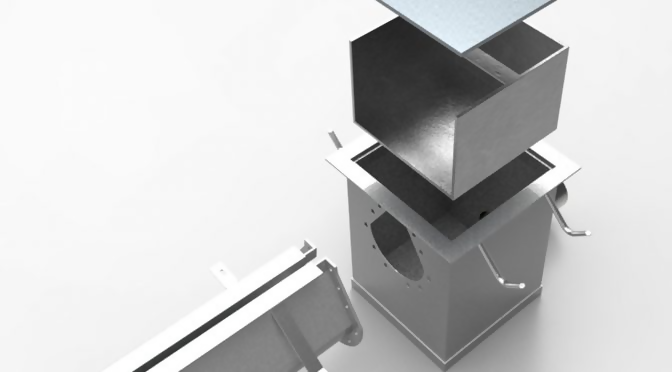

Solution: Slot Drain Offers Heavy-Duty Systems

Slot Drain has drainage systems for all types of applications, including industrial facilities like paper and pulp mills. Their industrial systems are built with the ability to handle the weight of the various machinery and equipment of production and processing facilities. For these facilities, they have the 9000 Series, which is a Load Class C system, meant for regular commercial use, such as paper and pulp mills. There is also the heavy-duty 10,000 Series system, which can take up to 10,000 pounds of weight and is even safe for airport use.

2. Grates are Heavy and Fragile

Another major issue with traditional paper and pulp mill drainage is that it requires a grate cover. These covers are heavy pieces meant to help prevent large debris from falling into the drain channel and causing backups. But, they can be more trouble than help–they are heavy to remove for drain cleaning and may break after just a few years. They also create additional costs, as they need to be replaced every time they break. Otherwise, they will be a safety hazard, since workers can trip over broken grates and get injured.

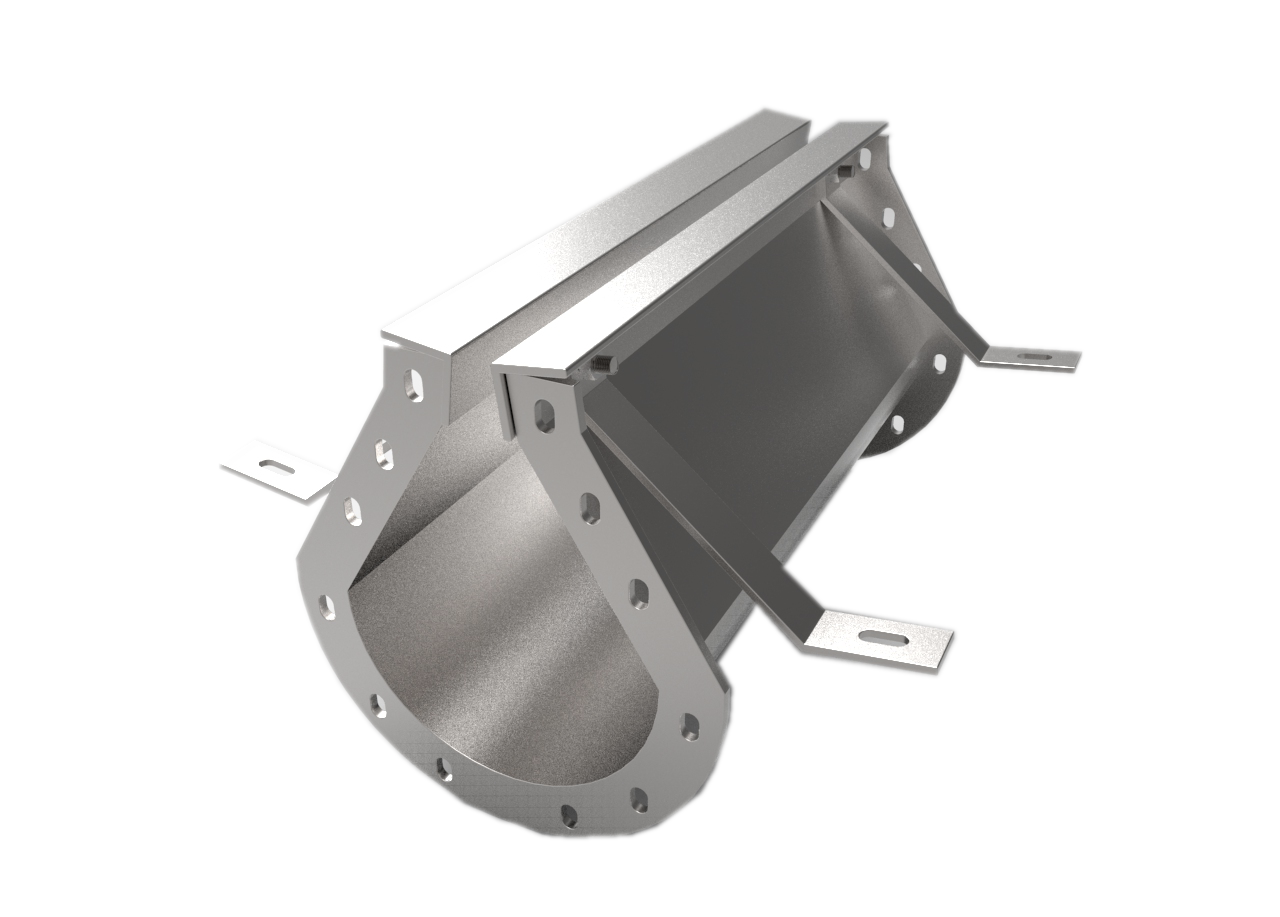

Solution: Slot Drain Has No Grates

What makes Slot Drain such a revolutionary system is that it does not require a grate cover. The slot opening of the system can range anywhere from .5-inches to 1.25-inches, making it slim enough that large debris will not get into the drainage channel. With no need for a grate, there is also one less step in cleaning the Slot Drain system, which helps make maintenance much more manageable.

3. Drains are Difficult to Clean

As mentioned before, traditional paper and pulp mill drainage systems require a heavy, cumbersome grate cover. For workers to clean the drain channel itself, the grate has to come off,and it is a potentially back-breaking job, that can cause employees to injure themselves. Beyond that, cleaning these traditional systems is a time-consuming process that requires multiple employees.

Solution: Cleaning Slot Drain is Easy

Slot Drain, on the other hand, is incredibly easy to clean. Part of the reason it is easy is because there is no grate to worry about removing at every cleaning. Slot Drain also offers unique features that can make the system virtually maintenance-free. Their commercial systems offer features that allow for more automated cleaning, including a Flush Flo and Clean inPlace system. Beyond that, to ensure the system is clean, workers can also use a simple brush and paddle to make sure no debris is left.

4. Drains Corrode with Chemical Use

Nearly all facilities use some sort of chemicals, either to help create their product, to clean, or both. If a paper and pulp mill drainage system is not made from the right material, it can lead to corrosion. Over time, the corrosion can become severe and the drain channel will weaken and break. It may also allow debris to cling to the walls, potentially leading to buildup or even bacteria forming from the moisture.

Solution: Slot Drain is Corrosion-Resistant

While Slot Drain can come in all types of materials, stainless steel is the preferred choice for the most durable drain possible. Unlike other drainage system material options, stainless steel is incredibly durable and corrosion-resistant. This means that, unlike other materials, a stainless steel system will not suffer from corrosion when exposed to acidic or corrosive materials on a regular basis.

The Better Paper and Pulp Mill Drainage System

Like with any kind of facility, paper and pulp mills require an efficient drainage system. But, the average drainage system has many potential problems that can be fairly significant. Because of that, you want to ensure that you choose the best possible system. The right system will have no issues handling the effective drainage for the facility.

Slot Drain's commercial systems (both the 9000 and the 10,00 Series) are the ideal choices.They offer solutions to common drainage problems, with well-designed, efficient systems. So, when it comes to paper and pulp mill drainage, there is no better option than the sleek, grate-free, easy-to-maintain, Slot Drain System.