There is a lot of planning that goes into the setup and design of something like a poultry processing plant. From the equipment to the floors, everything should get careful consideration. This includes the floor drainage system you choose to install.

You may not think of it as a big deal, but the drainage system is a critical part of any food processing plant, particularly one dealing with things like poultry. Here are some things to consider when thinking about the drainage system for your poultry processing plant.

First, Choose the Right Floor

Even without considering the drainage system, the floor you choose for your poultry processing plant is essential. Certain flooring types would work well in a poultry processing plants, while others may be an invitation for sanitation issues.

These floors are subject to a lot of rough treatment from machinery, cleaning, and the general nature of the plant. So, it is essential that the flooring is durable and easy to maintain.

In many cases, a concrete floor is what plant designers choose. But, the concrete gets treated with a particular type of coating to created added protection and durability. Coatings include epoxy, polyurethane, methyl methacrylate, and polyureas materials. It is essential to do the research to determine which will work best for a food processing plant.

Consider the Drainage System

There are different types of drainage systems available for all sorts of applications, including poultry processing plants. But, for such a place, you want to choose the absolute best, most effective system available.

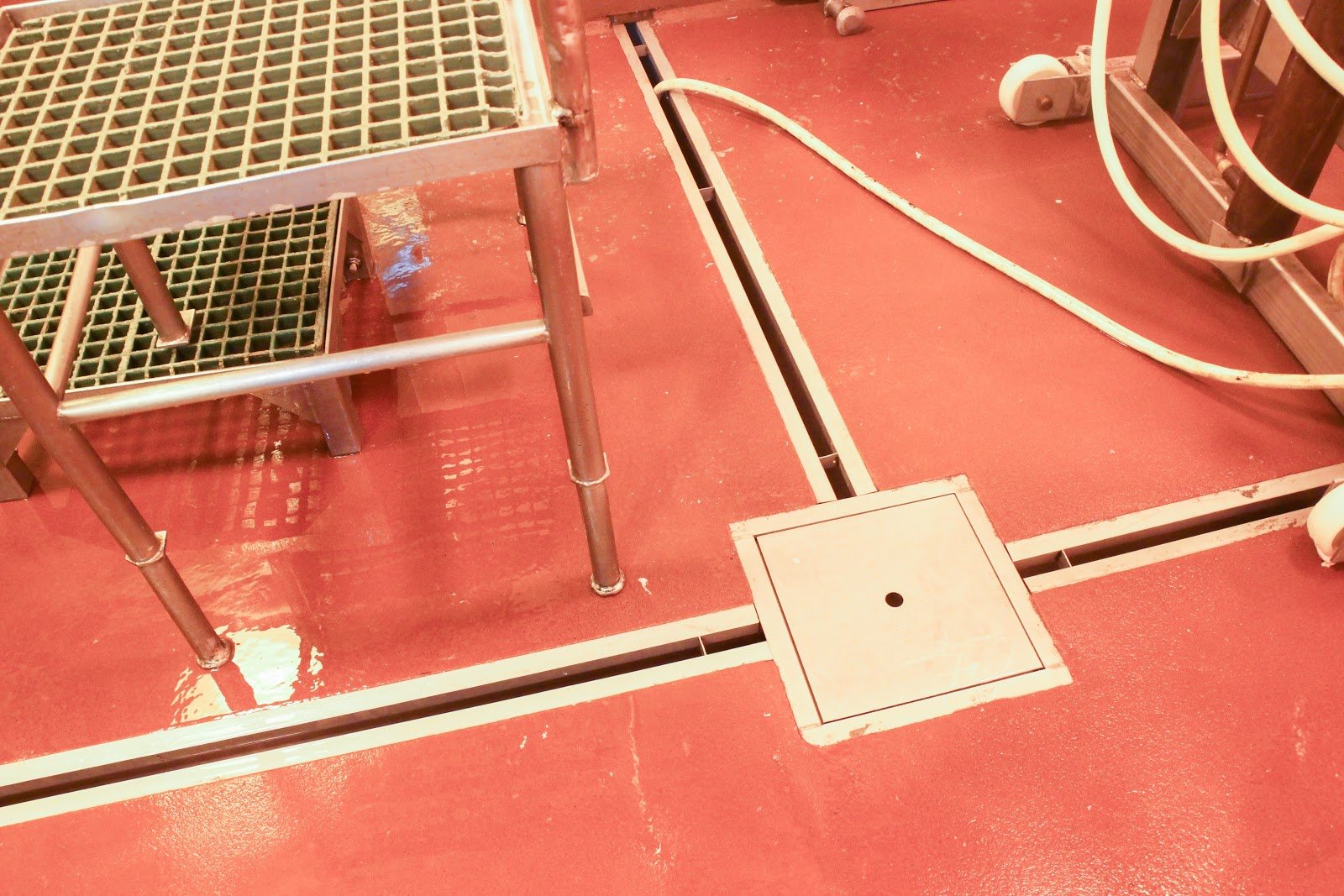

That is where the Slot Drain system comes in. Slot Drain is a newer, more efficient form of trench drain that eliminates many of the issues that come with traditional grated trench drains.

There are a number of factors that combine to make the Slot Drain System such a great option, but here are just three of them.

1. There Are No Grates

One of the most significant issues with traditional trench drains are the grates. They are big, heavy, break easily, and cannot handle heavyweight application.

The Slot Drain System eliminates these troublesome grates and creates a thin, streamlined drainage system. These systems also are much stronger and capable of withstanding up to Class F loads without breaking or failing under pressure.

Additionally, the lack of a grate makes the Slot Drain lay flat into the floor, without any lip that usually comes with a grate. This helps to make them more ADA-compliant and eliminates any potential tripping hazards.

2. Durable Stainless Steel Body

Something like a poultry processing plant requires materials that are approved by legal bodies like the USDA and FDA. The Slot Drain system meets both these organizations’ standards with their food-grade stainless steel drain channel construction.

Stainless steel is well known for being an incredibly durable material, capable of withstanding high heat and freezing temperatures with no issue. Additionally, stainless steel is extremely bacteria resistant due to it being a nonporous material. This means that bacteria will not stick to it, creating later sanitation and contamination issues.

A stainless steel body is also much easier to clean, and due to the corrosion resistance of it, you can use strong disinfectant chemicals to ensure a thorough cleaning.

3. Easier Maintenance

A poultry processing plant should have a drainage system that is easy to maintain and does not require extra attention, allowing workers to focus on the product more than anything.

The Slot Drain System is very easy to clean because the drain channel comes pre-assembled as long, single pieces. This allows one or two workers to use a brush and paddle to clean it without having to worry about particles getting trapped on connecting joints.

Another great thing about the Slot Drain System is that there are options for self-cleaning and flushing systems, which make maintaining the drains clean an even easier job.

The Placement of the Drains

Finding the right floor coating and choosing the Slot Drain System is just part of the plant design process. You also need to consider the overall setup and placement of the drain channels.

Every area of your facility should have a drain channel in the floor. But, the placement should be strategic; you cannot just put them anywhere in the room and expect them to be effective.

Take time to consider the layout of each area and where the actual work is getting done. The drain channel should go somewhere near that area, but also be near a water hose or cleaning station, to allow for easier cleaning throughout and at the end of the day.

These are just a few things to consider when it comes to designing the perfect poultry processing plant. It is critical that you take the time and access every aspect and every material before you make a final decision on what products and materials you want to go with your plant.

The Slot Drain System is one aspect that is the superior option in terms of durability, efficiency, and cost. You are sure to see the benefits immediately, and it will not disappoint.

Food Safe Drains contains several articles for food and beverage facilities researching the best types of drain systems for their applications.