When people think of issues like Salmonella and Listeria, they usually don't think of it as referring to bacteria in ice cream. But, what many don't realize is that bacteria has the potential to infiltrate any facility, including ice cream producers.

Just like with any food, ice cream bacterial contamination is a serious concern not to be overlooked. By law, ice cream makers must ensure their products are uncontaminated; otherwise, they cannot ship or sell them.

Unfortunately, contaminated ice cream is not uncommon. For that reason, ice cream producers must follow the FDA and USDA guidelines carefully, to prevent the possibility of Listeria in ice cream.

The Outbreak of Listeria in Ice Cream

Earlier this year, the FDA released a report based on the findings from a study of ice cream producers. With this report, the FDA examined the findings of both Listeria and Salmonella in ice cream contamination by various ice cream producers.

The FDA's report analyzed 89 ice cream producers from 32 states, between September 2016 and August 2017. It noted 16 different ice cream recalls due to the presence of bacteria in ice cream.

In 2015, the CDC also released information about ice cream contamination that led to 10 individuals becoming sick after eating Listeria-contaminated Blue Bell Creamery ice cream. However, the outbreaks were said to date back to 2010, when hospitals also gave the ice cream to sick patients. In some cases, these recalls led not only to sickness but death, due to the severity of the contamination.

What Causes Ice Cream Contamination?

When a factory is unsanitary, there is a more significant possibility of an ice cream bacterial contamination occurring. This potential contamination is primarily because a facility is not properly cleaned.

Ice cream producers often work in cool, wet environments that provide the perfect breeding ground for various forms of bacteria, such as Listeria and Salmonella. The longer areas are left wet, or puddles of water are left sitting, bacteria will begin to grow. These bacteria will spread due to workers moving around, and will float into the air where it can then contaminate the ice cream in production.

Avoiding Contaminated Ice Cream

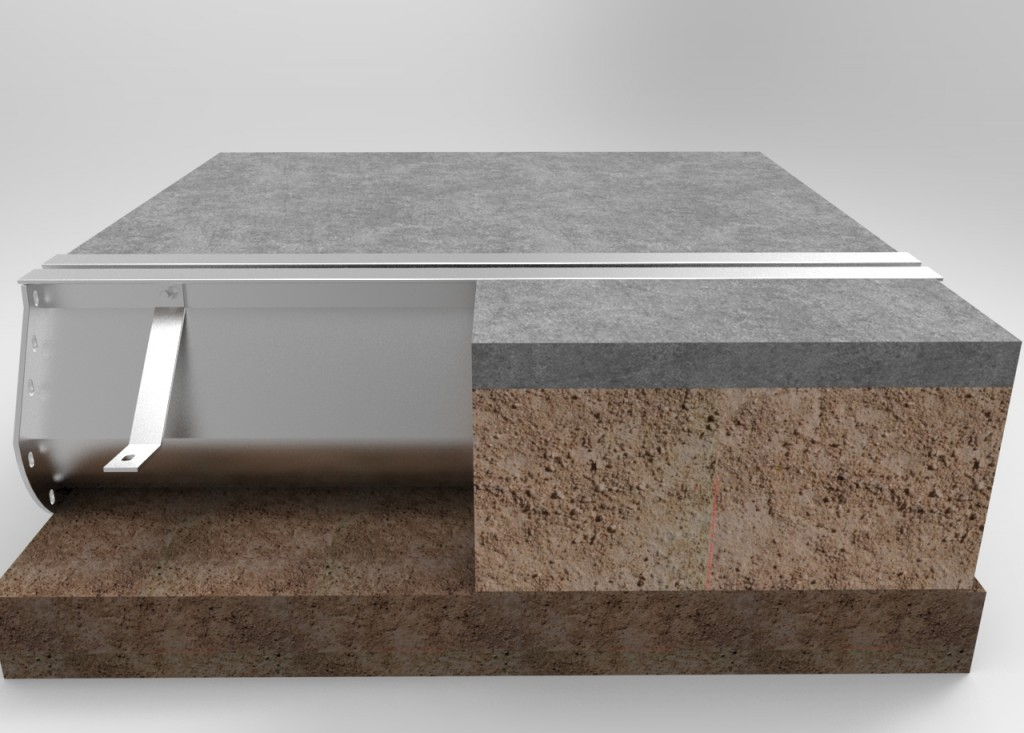

The easiest way to avoid issues such as Salmonella in ice cream is to maintain a sanitary facility. To prevent bacteria in ice cream, facility owners must clean their facility regularly. One thing that facility owners can do to help create a sanitary, bacteria-free facility is to install a high-quality surface floor drain.

Floor drains assist in the management of wastewater. They trap dirty water and prevent bacteria and contamination from spreading throughout the facility. With that, they also help to ensure the floors remain clean and dry, also ensuring that workers will not slip or fall as they move throughout the facility.

Benefits of Surface Drains

1. Minimize Bacteria Growth and Contamination

As mentioned earlier, ice cream contamination is a severe issue. But, due to the facility conditions of ice cream producers, they are prone to bacterial growths like Listeria and Salmonella, which can be deadly.

While a drain will not completely eliminate the risk of bacterial contamination, it can make a significant difference. This is because, when made of non-porous stainless steel, a drain channel can trap bacteria and help prevent it from spreading.

2. Keep Floors Dry

With the amount of moisture that can come from dealing with wet, cold products, there is always a chance of water gathering on the floor. Standing water can lead to bacteria growth and things like Listeria in ice cream. But, it can also lead to wet, slippery floors that workers can slip and fall on.

A floor drain will have a sloped build so that any water will flow toward the drain and away from the floor surface. This will keep the floor clear of water and allow it to dry faster so that there is no chance of bacteria growing or accidents happening.

3. Handle Wastewater

In general, another major benefit to a surface drain is that it handles wastewater. Any wastewater will flow to the drain channel, where it can then go directly to a catch basin. This will help to make cleaning the facility easier and ensure that dirty water is not left standing.

Slot Drain to Prevent Contaminated Ice Cream

For a high-quality, durable surface drain system, consider the Slot Drain system. This system is a trench drain that comes both pre-sloped and pre-assembled, making it easier to install than other systems. It is made of a non-porous, food-grade stainless steel that is bacteria and corrosion resistant.

Beyond that, stainless steel is durable enough to handle the cold temperatures that come with an ice cream production facility. Slot Drain, in particular, also overs a Load Class F, which allows it to handle the heavy weight of factory machinery.

The Slot Drain is very easy to maintain. There is an option for a self-clean or flushing system, which takes out much of the work required for cleaning. Since it is corrosion resistant, this also means that strong cleaning chemicals will not damage the system during the cleaning and sanitation process.

In general, all of this makes it a great option to try and prevent contaminated ice cream or other food products from being an issue.

Salmonella in ice cream is, unfortunately, a common issue. However, it is incredibly dangerous and can have deadly results. Because of that, it is vital to take the time and understand the FDA and USDA ice cream facility requirements. Doing everything possible to prevent contamination in ice cream will help to avoid a bacteria outbreak that can ruin a company's reputation. One simple thing to do is to install a stainless steel drainage system, like Slot Drain, to help create a drier, more sanitary facility.

Food Safe Drains contains several articles for food and beverage facilities researching the best types of drain systems for their applications.