1. Add Sloped Tops to Surfaces

One of the most important things to do is to prevent the pooling of water, which can keep surfaces from drying fast enough. The surfaces of ductwork and electrical cabinets can often get overlooked, but moisture and water can very easily collect on these surfaces, which can, in turn, lead to the growth of harmful bacterias. By ensuring that the tops of various surfaces are sloped, you ensure that water does not collect, so the surfaces will dry more efficiently.

2. Have Properly Sloped Floors

Even more important than ensuring that the tops of surfaces are sloped is ensuring that your facility's floors are sloped. Sloped floors will ensure that, instead of pooling, any water can flow to the drain channel, keeping the floor free from puddles.

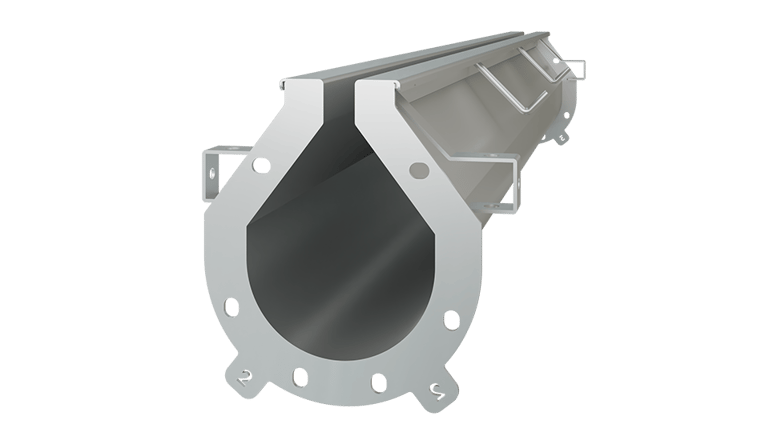

3. Choose the Right Drainage System

In addition to having sloped floors, a sanitary facility and equipment design also requires you to ensure that you have the right drainage system to handle your facility's fluid waste. Everything from the type of facility to the amount of fluid waste you deal with needs to be taken into consideration. Slot Drain makes drainage systems for all types of applications, including industrial facilities. Their grateless trench drains are sanitary, strong, and resistant to many things, including bacteria.

4. HVAC Systems Should Have a "Purge Mode"

HVAC systems can be incredibly helpful in removing excess moisture from an area. You should ensure that your facility's system includes a "purge mode" that uses exhaust fans to help remove lingering water mist. It will reduce the amount of water in the air and also reduce the amount of water collecting on the surface, so that rooms can dry more easily.

5. Facility Design Matters

Facility design is also an essential part of sanitary facility design. Facilities should have a layout that makes sense for each of the steps in processing, going from the raw materials to the final product. Processing rooms also need to be big enough to comfortably fit employees and equipment, with space to spare around the perimeter, which will allow for access to all areas of the facility, ensuring a thorough cleaning.

6. Have Sufficient Lighting

Lighting needs can sometimes be overlooked, but it is an essential part of any facility. Aside from allowing workers to see clearly the various jobs they do, it will also allow workers to clean more efficiently. With sufficient lighting in place, workers are less likely to miss dirt, debris, or spills that need cleaning.

7. Plan for Proper Drain Layout

With a proper facility design and sufficient lighting, you also need to consider the drainage layout. Floor drains need to be strategically placed in order to ensure optimal efficiency. It is essential to ensure that these drains are not covered or blocked by equipment. Proper drain layout will also help to ensure that all parts of the drain are easy to reach so workers can clean it thoroughly.

8. Ensure Cleanability

Having a sanitary facility and equipment design means ensuring the cleanability of the facility and equipment. While clean-in-place and clean-out-of-place systems are incredibly useful, they are only effective if all areas can be reached. Ensuring the cleanability of the facility means avoiding things like pipe slopes, varying pipe dimensions, right angles, gaps, and equipment that is difficult to disassemble or too large to clean in a single piece.

Fixing Older Plants to Meet the Standards

While it is incredibly easy to work these sanitary facility and equipment design ideas into a new facility, it takes more work with older facilities. Older facilities tend to have degrading drain systems and outdated designs that don't meet today's strict building codes. As a result, implementing these design ideas takes more effort. However, it is essential to creating a safe and sanitary facility that is less likely to keep bacteria from forming and spreading. These facilities need to be updated in every way, from the lighting all the way down to the floors and drainage systems.

Water is the biggest culprit in the growth of bacteria within industrial facilities. Therefore, you must do everything you can to ensure that your facility is designed to manage water and water runoff efficiently. By implementing these design ideas, you can ensure that your facility is handling fluid waste properly, and you will not face any bacteria growth or contamination issues. While there are plenty of steps you can take to ensure a sanitary facility and equipment design, starting with anything related to moisture, water, and drainage is the right place to start.