One of the critical features every brewery needs is a proper floor drainage system. These drainage systems help to manage liquid waste and maintain a clean and sanitary facility which is certainly one of the most important keys to a successful brewery.

While breweries legally require a drainage system, the USDA and FDA do provide at least some flexibility with their requirements. For example, breweries can choose from different drainage material options, as long as they fall into the specified parameters.

Importance of Drainage Material

The drainage channel is what makes the entire drainage system function. It helps to catch all sorts of waste and fluids in order to maintain a clean and sanitary brewery.

Due to the nature of breweries and the sorts of fluids and waste they regularly create, drainage systems require a durable construction. Drain channels should use nonporous and noncorrosive materials that can withstand varying temperatures without the worry of them cracking or breaking. The more durable the chosen drain material is, the better it is for the brewery. A common debate for brewery drainage is stainless steel vs. polymer concrete as the chosen drain material. Here is a brief comparison of the two, to help make deciding easier.

Stainless Steel

Stainless steel is a highly durable, nonporous metal material used in a wide range of applications, including as drainage systems.

Stainless steel also has the benefit of being a noncorrosive material, capable of handling caustic substances with ease. It is also an extremely bacteria-resistant material, so there is no need to worry about bacteria accumulating and growing within the channels like there would be with other materials.

Beyond that, it is a recyclable material that is easier to install than other drain channel materials and even allows for easy retrofitting.

Other benefits to stainless steel drainage systems include its ability to handle heavy weight, so there is no worry of it breaking under the pressure of heavy brewery machinery. Additionally, it is easy to clean and maintain, and will not retain odors like other, more porous drains might.

Unfortunately however, because of these countless benefits, stainless steel drain systems can also prove to be a little more costly than other options.

Polymer Concrete

On the other side of the stainless steel vs. polymer concrete debate, there is polymer concrete. Polymer concrete comes in many forms, but the one best suited for brewery drainage systems is called polycast. This is a material that is a unique blend of vinyl ester resin and concrete, which creates a very durable material.

Like stainless steel, it is strong, capable of handling caustic substances, and also able to withstand high temperatures without issues. It is also more economical than stainless steel as an initial install.

However, installation of a polymer concrete drainage system is more complicated, and time-consuming, and retrofitting is not as easy. Additionally, polymer concrete drainage systems require a grate covering, which can be cumbersome and fairly fragile, requiring replacing every few years. This means an added cost, especially since you will want to invest in the more costly iron grates, which can withstand heavy loads better.

Grate coverings also make for a more time-consuming cleaning job, so maintaining polymer concrete drains is a more involved process.

The Final Debate: Stainless Steel vs. Polymer Concrete

In terms of stainless steel vs. polymer concrete for a brewery drainage system, each has its benefits. However, when it comes down to it, you want an easy to care for and durable system for your brewery. For that, there is no better option than a stainless steel drain system.

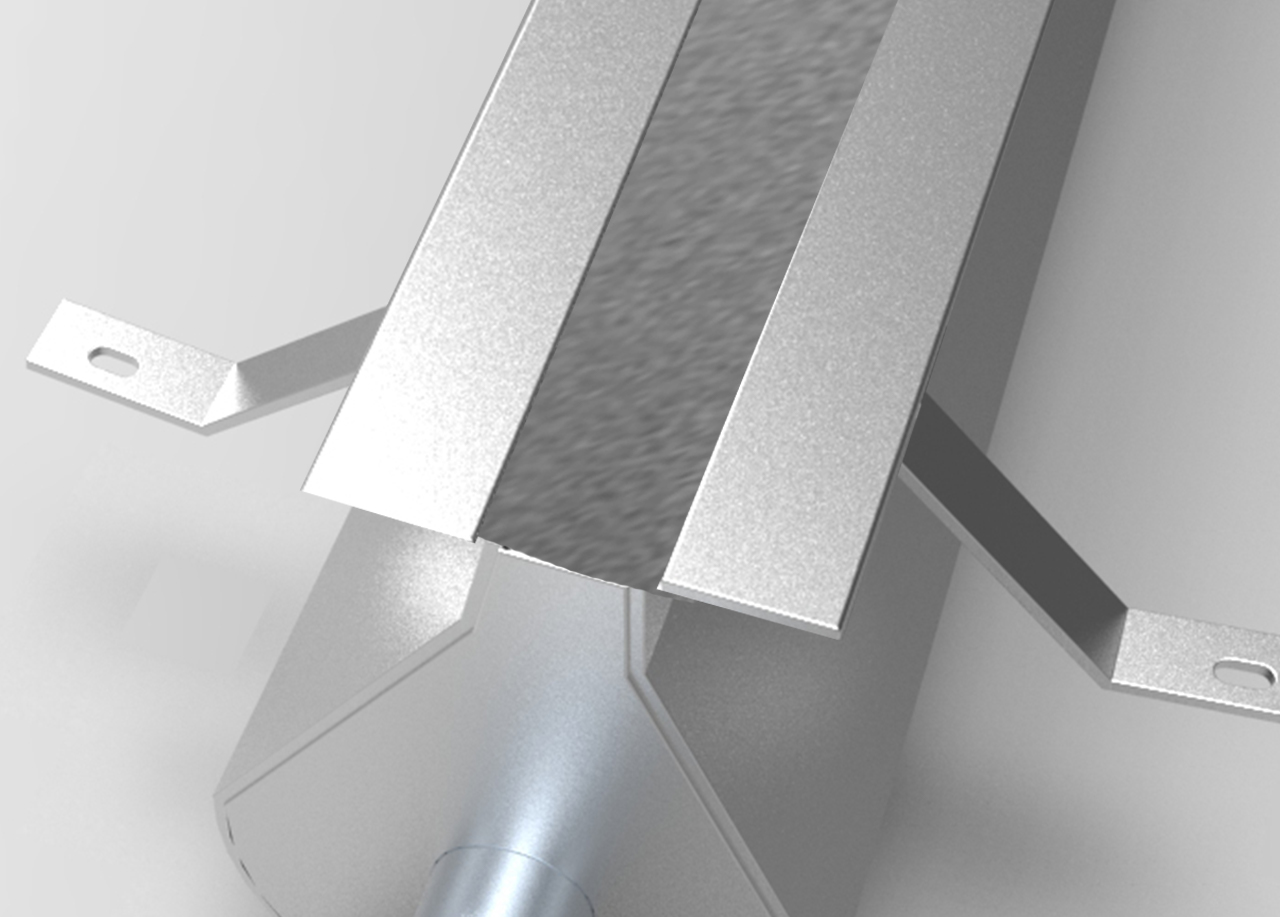

One company that makes an efficient system, and has many happy clients, is Slot Drain. Their innovative stainless trench drain system is an aesthetically pleasing system that does not require a grate covering. Beyond that, it can support up to Load Class F rated loads, making it an incredibly strong system that will not break under the pressure of heavy brewery machinery.

Slot Drain has the added benefit of also offering self-cleaning and flushing systems that breweries can also have installed. These systems help to make cleaning and maintaining the drainage system much easier and hands-free.

This system also can be ADA compliant, which helps to minimize the risk of people falling or becoming injured on the drainage system.

Many things go into the designing and planning of a brewery. Your floor drainage system deserves as much consideration as the ingredients you source for your beers. There is plenty of debate between stainless steel vs. polymer concrete as a drain channel material, but you want to choose the absolute best you can for your facility. For that, you want to choose a stainless steel drainage system like Slot Drain.

This system has countless benefits going for it and is guaranteed to last for years and never give you any issues. The initial cost may be slightly higher, but in the end, you will be happy to have invested in it for everything you get back in return, not to mention the value of having peace of mind in your drainage system. So, look no farther than a stainless steel Slot Drain for your brewery drainage needs.