Food processing facilities are held to undeniably high standards, with good reason. These facilities are, in large part, responsible for the safety of the food that people consume in civilized countries all over the world. Without careful attention to food safety, a facility can experience serious issues, like poor sanitation, leading to contamination and product recalls. As a facility manager, it is your responsibility to ensure everything is up to code. Audits help to ensure that food processing plants are following safety standards and operating appropriately.

Here are several tips on how to prepare for a food processing safety audit, so you can ensure that your facility does well.

Train All of Your Employees

One of the most critical steps to running a safe facility is training your employees. A well-trained employee will have a firm understanding of their job within the facility and perform the tasks while meeting the food safety standards. Ideally, you also want to cross-train your employees so that you can move employees around to keep the facility running smoothly, even if you are short-staffed. Training shouldn't be a one-time event. Cross-training provides greater flexibility for your facility employees and also gives them additional job skills.

Use PPE Equipment

Part of knowing how to prepare for a food processing safety audit is ensuring that all employees dress appropriately. Wearing the wrong clothes can lead to accidents or contamination by introducing contaminants into the sanitized processing area.

Preventing contamination requires thorough hygiene practices and the use of PPE or personal protective equipment. Using PPE equipment means you minimize the risk of contamination and ensure that employees are safe from the possibility of cuts, burns, or other injuries that can result from improper clothing.

Do Your Own Pre-Audit

To ensure that your facility can pass food safety audits, consider conducting a pre-audit.

A pre-audit would consist of running through an audit checklist, and making sure your facility meets the required food processing safety standards. You would take that time to look at your set-up, talk to your employees, quiz them, and find any faults that could negatively impact you. Once you have done the pre-audit, you can go back and fix any issues in order to ensure that you pass all safety audits. Performing pre-audits at least once a year can help ensure that your facility is running safely and it will allow you to address any issues and make continual improvements.

Prevent and Reduce Insects in Your Facility

You don't want insects in your facility; they carry germs and diseases, resulting in serious contamination issues. Once you have bugs in your facility, they can be impossible to get rid of–so preventing them from entering is vital. During an audit, the auditing team will look for the steps you've taken to prevent insects from entering, like ensuring that there are no cracks or crevices for them to get through. You can also use insect-attracting lights outside of the facility to help prevent them from getting inside. Maintaining a clean and sanitary facility is essential to reducing insects, as food waste is the primary culprit for attracting them.

Make Use of CIP Systems and Practices

https://www.slotdrainsystems.com/food-and-beverage-industry

Employee training is important, however, nothing is more critical than the cleanliness of your food processing facility. It is a primary concern during audits, to ensure that facility managers are taking the appropriate steps to clean and sanitize their facilities. Ideally, you want to employ various cleaning practices and techniques within your facility, including clean-in-place (CIP) practices. CIP systems are automated cleaning systems that clean the interior surfaces of equipment within a food processing facility without disassembling any equipment. These surfaces include processing machine pipes, tanks, mixers, blenders, roasters, and much more.

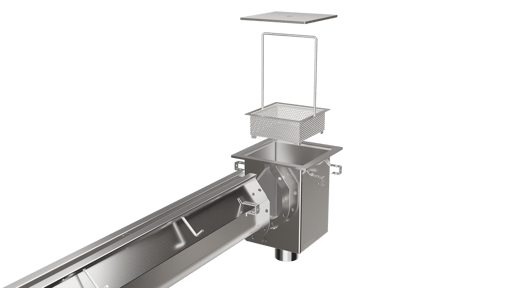

Choose the Right Drainage

https://blog.slotdrainsystems.com/hygienic-food-processing-drainage

Food safety auditors inspect food processing facilities thoroughly to ensure that they meet all safety standards. A key factor they will look for is a floor drainage system. Floor drains divert wastewater and other fluid waste from the floor surface into a drain channel, keeping floors clean and preventing contamination. The 9,000 Series and 10,000 Series systems from Slot Drain are industrial-level systems made from FDA-approved, food-grade stainless steel. These two systems are corrosion- and bacteria-resistant, making them ideal for food processing facilities. The linear systems also have a unique, grate-free design, making them easier to clean and maintain, especially with CIP capabilities.

Make Your Food Processing Plant Successful

As a food processing facility manager, knowing how to prepare for a safety audit is important. Taking the time to prepare your facility and employees for the audit will ensure a successful and smooth auditing process. These are just some of the more important steps you can take to prepare, but by studying the food processing safety standards that apply to your facility, you can do even more to ensure that things go well for you. Adding a new drain system may be an added expense, but it is worthwhile to create a cleaner and more sanitary facility. Overall, all of these improvements lend themselves to bettering your facility and protecting your employees and products.

The drainage experts at Slot Drain are prepared to assist you with specialized equipment and years of sanitization expertise. Contact us today for more information on preparing for a food safety audit and drainage products designed for food facilities.