Having the right drainage system in place is vital for any facility to work well. Among other things, a drainage system helps keep the facility clean, sanitary, and odor-free.

But, not all drainage materials are made equal. It is crucial to consider the different materials available and choose the best option.

Two common materials facility owners look at are stainless steel vs. vinyl ester. Here is what you need to know about each of these options, and which one is best overall.

Stainless Steel

Stainless steel is a highly durable form of metal that has a wide range of applications, including drainage systems. Stainless steel is an excellent material for any drainage system, but particularly for areas like food, beverage, farm, and medical.

Advantages

Non-Porous Material

One major advantage to stainless steel drainage systems is that stainless steel is a non-porous material. This means that the drain channel has no cracks, crevices, or other ridges for bacteria and waste to get caught in. As a result, the drain remains cleaner and more sanitary,

Bacteria Resistant

Another significant advantage to stainless steel is that it is bacteria resistant, in addition to being non-porous. It’s less likely to have issues with bacteria growth and contamination, which makes stainless steel drain construction ideal for many different facilities where sanitation is critical.

Corrosion Resistant

Stainless steel is also highly corrosion resistant, which means it can handle strong chemicals without eroding or degrading. This makes stainless steel, again, a top contender for facilities where there is a lot of chemical exposure.

Heat and Cold Resistant

Stainless steel is also popular for its ability to handle both hot and cold temperatures well. This makes it ideal for use in food and beverage handling facilities, where different areas require varying temperatures. The stainless steel can handle these changes without issue and will continue to function as normal.

Easy-to-Maintain

Once a stainless steel drain is installed, there is very little required maintenance beyond cleaning it with the appropriate cleaning implements. Because it is a non-porous, chemical resistant material, it is easy to run cleaning chemicals through it and rinse the whole system of any waste.

Disadvantages

Price

The bigger the system, the more you will have to pay for a stainless steel drain, usually. This can pose an issue, depending on the facility's budget.

Vinyl Ester

Another common drainage material is vinyl ester. It is produced from the reaction of an epoxy resin and an unsaturated monocarboxylic acid. Essentially, it’s comprised of a polyester resin base and strengthened with epoxy molecules to form this new material.

Advantages

Water Resistant

Compared to other drainage materials, vinyl ester is very water resistant. This makes it a wonderful option for drainage, particularly in facilities where there is more frequent liquid exposure.

Durable

Another benefit to vinyl ester is that it is more tolerant to stretching and stress than the average polyesters. Because of this, they are better able to absorb the force of an impact without suffering too much damage. This also means they will show less stress cracking.

Withstand Strong Chemicals

Due to the chemical composition, vinyl ester is also relatively resistant to acids, chlorinated solvents, and other caustic materials. This makes it suitable for drainage, as it can withstand the strong cleaning chemicals some facilities rely on for cleaning.

Disadvantages

Shrinkage

While shrinkage is minimal, it still occurs during the curing of a vinyl ester drain system. This shrinkage needs to be accounted for, to ensure the drain is poured correctly to fit the final, cured drain system.

Cost

When comparing stainless steel vs. vinyl ester, vinyl ester is still a costly option. It is important to evaluate the facility where the drainage system is needed to ensure it is worth the investment. For vinyl ester to handle the weight of heavier equipment, it requires a different mixing and pouring method to ensure its strength. As a result, this can cause it to cost more to install.

Chalking

Unfortunately, while vinyl ester is durable, it is still susceptible to chalking. Chalking is the term that describes the UB breakdown of the surface of the drain system, which can degrade it over time. While there are additives you can add to the mix to prevent this, it is another cost to consider.

Which Option is Best for Your Drainage System?

When considering stainless steel vs. vinyl ester, there are many different things to keep in mind. But, when it comes down to it, you’ll want to choose the most durable, easy-to-install, and east-to-maintain option.

While stainless steel may seem more costly at first glance, once it is installed, there is no need to worry about repairs or replacing parts. It will continue to work for the lifetime of the facility.

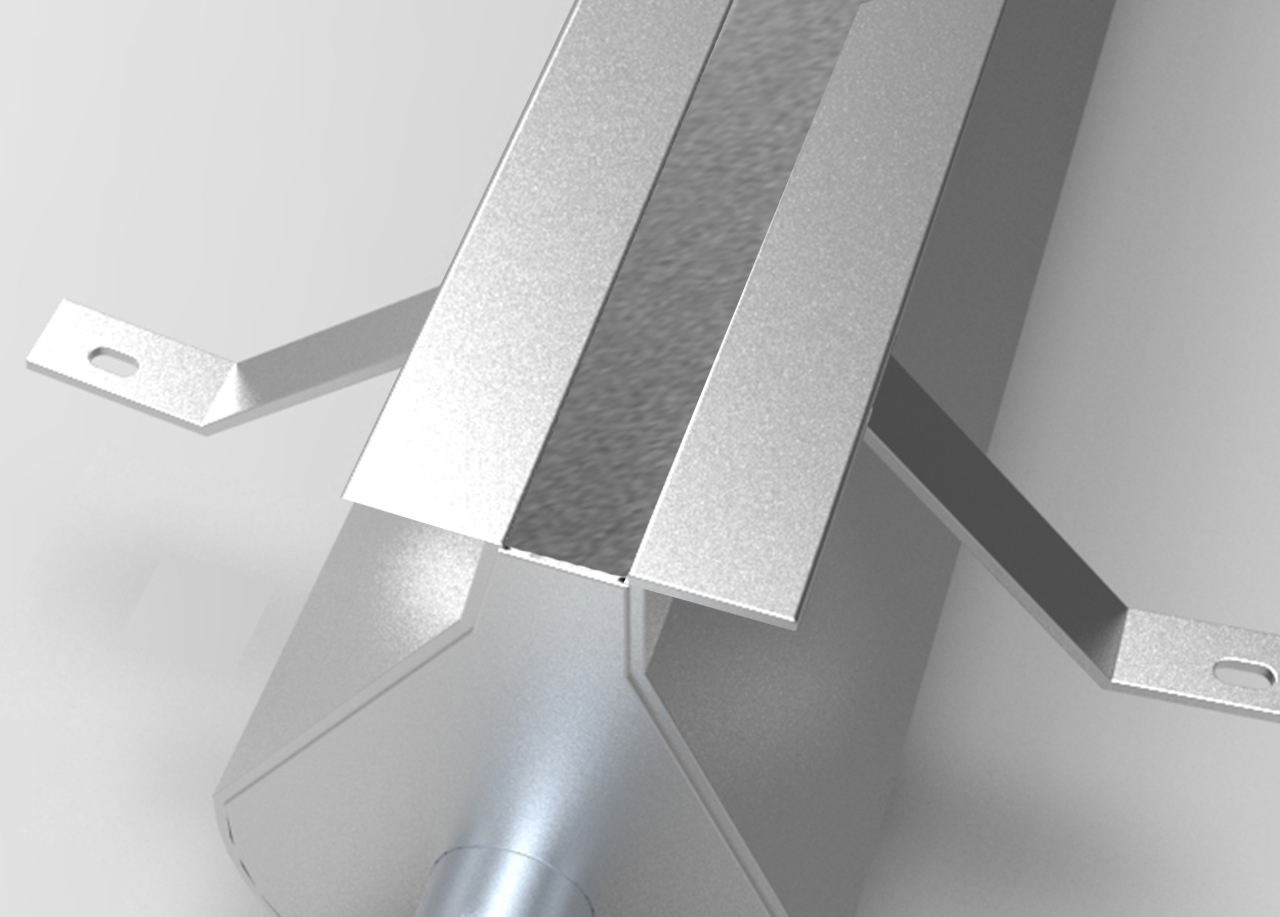

The Slot Drain

Slot Drain is a company that specializes in stainless steel trench drain systems that are a little different from the ordinary trench drain. Their drain systems are unique in the sense that they come pre-sloped and pre-assembled as a single piece, making installation a breeze. Beyond that, the Slot Drain System requires no grate covering, which means there is one less piece to the construction.

Finally, slot drains are incredibly strong–capable of Class F loads, the heaviest possible load system on the market. This means they will do well in any facility, from airport hangars to breweries.

Choosing the right drainage system for your facility is essential. You’ll want to choose one that is strong, durable, and will last a long time. When comparing stainless steel vs. vinyl ester, there is no denying that they are both strong, durable materials.

However, stainless steel still has more to offer than vinyl ester. Because of that, you should consider a stainless steel drain system, like those from Slot Drain, for your facility. It is easier to install, easier to maintain, more durable, and will handle the job even better.